India’s textile sector is undergoing a significant transformation; one driven by the urgent need to balance economic growth, cultural heritage, and environmental responsibility. With challenges such as waste management, traceability, and the growing threat of greenwashing, the rise of innovation-led enterprises comes at a crucial moment.

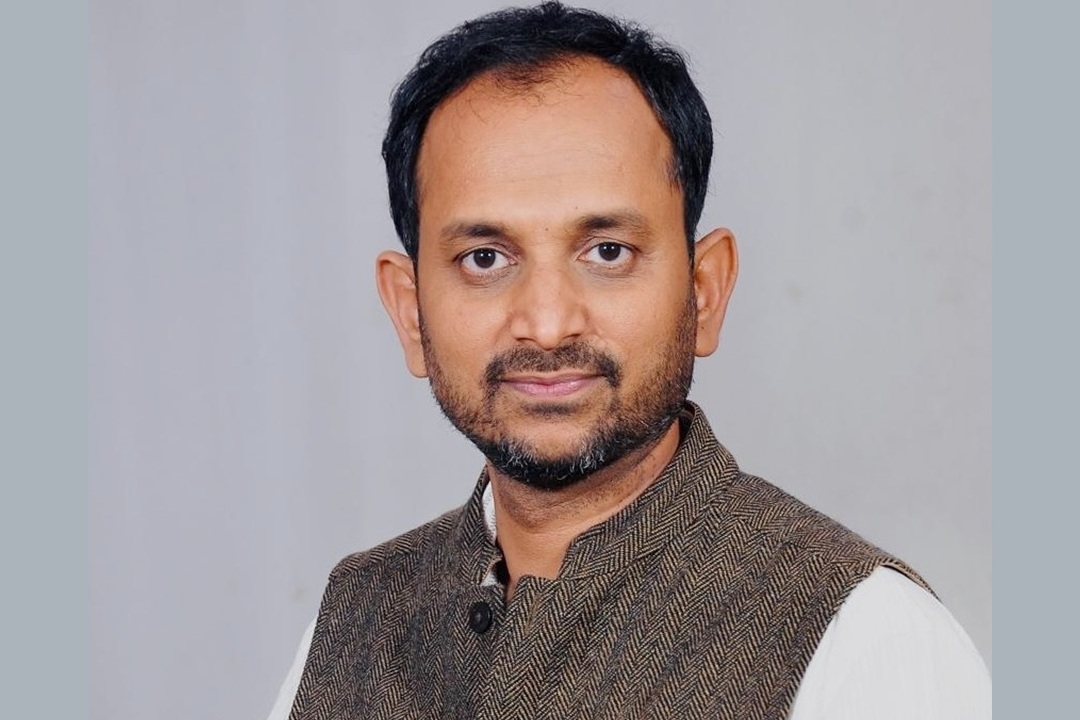

One such enterprise is KOSHA.ai, co-founded by Vijaya Krishnappa, a textile engineer and XLRI alumnus whose expertise spans technology, sustainability, and policy. Recognized by global platforms and working closely with research leaders such as IISc and C-CAMP, KOSHA.ai is not merely developing compliance tools, it is enabling India’s weavers, waste pickers, and textile MSMEs to adopt traceability and measurable sustainability.

In this exclusive interview, Vijaya Krishnappa shares how KOSHA.ai’s pioneering approach is making authenticity measurable and championing circularity across one of the world’s most complex supply chains. We explore the company’s journey, vision, and real-world impact—offering a front-row view of how purpose-driven technology can restore trust, strengthen livelihoods, and accelerate accountability across the textile ecosystem.

Read on.

Q&A

Q. Could you tell us how KOSHA.ai began and what inspired you to bring technology, textiles, and sustainability together? What core problem were you hoping to solve when you started?

A. KOSHA.ai began with a simple yet urgent question: how can we bring truth and transparency back into textiles? Having worked in the fashion and textile ecosystem for years, we saw first-hand how counterfeiting, greenwashing, and fragmented supply chains were eroding both trust and livelihoods. Handmade products were being undercut by machine-made fakes, and genuine sustainable efforts often went unrecognized. It became clear that if we wanted a truly circular and equitable industry, we needed to make authenticity measurable.

That’s how KOSHA.ai was born - at the intersection of technology, textiles, and sustainability. We started by building tools that could scientifically verify material composition and trace a product’s journey from fibre to finish. Our goal was not just to digitize the supply chain, but to humanize it - enabling transparency for brands, fair value for makers, and trust for consumers.

Q. The textile industry is one of the biggest generators of waste worldwide. How is KOSHA.ai using technology to change the way textile waste is seen and handled — from something to discard, to something of real value?

A. According to the UN Environment Programme (UNEP), the world produces nearly 92 million tonnes of textile waste every year, yet only 15–20 percent is collected for reuse or recycling. Of that, less than 1 percent is recycled back into new clothing (Ellen MacArthur Foundation, 2023). In India, textile waste is estimated at about 7.7 million tonnes annually, roughly 8.5 percent of the global total, and studies show that nearly 48 percent of post-consumer waste could be recycled if sorted effectively (KPMG India &

Intellecap, 2022).

At KOSHA.ai, we are redefining how this waste is perceived, not as an endpoint, but as a resource. Our AI-powered material identification and NIR-based scanning technology detect fibre composition with precision, enabling recyclers to sort and grade feedstock accurately.

Our traceability platform then tracks every batch, from collection to recycling to remanufacturing, ensuring transparency, accountability, and measurable impact. By combining AI, IoT, and Digital Product Passports, we convert waste data into material intelligence, transforming discarded textiles into verified, valuable raw materials.In essence, KOSHA.ai is helping the industry move from a linear “use-and-discard” model to a circular “use-and-renew” system, where textile waste becomes the foundation of a more resilient and regenerative future.

Q. You often talk about sorting as the first step toward circularity. Why is proper sorting so critical, and how does your technology make it smarter and more efficient?

A. We know that the fashion industry is one of the most polluting in the world, generating millions of tonnes of textile waste every year. As the second-largest textile producer, India contributes significantly to this challenge. Much of this waste ends up in landfills or is incinerated, creating enormous environmental pressure.

Recycling offers a vital solution, but one of the biggest bottlenecks has always been accurate fibre identification. Cotton, polyester, silk, and wool are all fibres with distinct molecular compositions that require different recycling processes. Yet for decades, waste pickers and sorters have relied on touch and feel, a method that is slow, errorprone, and inefficient.

Our innovation, FibreSENSE, changes that. This state-of-the-art molecular fingerprinting device instantly identifies fabric composition with a simple scan. FibreSENSE can detect whether a material is cotton, polyester, viscose, or a blend, making sorting simple, fast, and highly accurate. By enabling precise fibre identification, KOSHA.ai is helping recyclers move beyond downcycling and upcycling toward true circular recycling, reducing landfill waste and turning discarded textiles into resources of real value.

Today, FibreSENSE is being used by Textile Recovery Facilities (TRFs) across India. We’re also in the process of sending our FibreSENSE device to Italy this month for our first international deployment.

Q. Many people fear that AI will replace human jobs, but your work shows a different side — where AI supports and uplifts workers. Can you share how KOSHA.ai uses technology to make work safer, cleaner, and more dignified for people in waste management?

A. Our technology is designed for the waste workers and decentralised setups at the heart of the textile waste ecosystem. Waste workers and manual sorters areempowered through local language integration, audio prompts, and bin-color guidance, mobile phone integration, improving both dignity and income opportunities. An added layer of traceability is managed through a simple mobile app, enabling decentralized workers to track and showcase the impact of their work.

Impact on Waste Workers

- Improves hygiene and safety: The device is operated while wearing gloves, promoting hygiene and safety, something nearly impossible with traditional “touch and feel” sorting.

- Builds digital and technical skills: Introduces frontline workers to accessible, techassisted tools that upskill them and add prestige to the waste picking profession

- Reduces attrition: One of the biggest challenges at TRFs is high turnover and the constant need to reskill new workers. No new training is required for someone using FibreSENSE.

- Improves income potential: More accurate sorting means higher-quality feedstock, leading to greater value for recyclers and fairer compensation for workers.

- Drives scalability: By improving material quality at source, FibreSENSE makes recycling more reliable and profitable across the textile value chain.

A leading example is our team member, Sangeetha. Coming from a family of waste pickers, she is now at the frontline of using FibreSENSE to transform textile sorting. She has already helped divert 12 tons of textile waste from landfills into recycling channels, proving how technology can create inclusive climate solutions.

Q. How do you co-create your solutions with recyclers, waste workers, and textile clusters, and what has this taught you about building technology that truly works on the ground?

A. We believe we are value co-creators and collaboration is at the heart of KOSHA.ai’s innovation model. We work directly with mills, recyclers, waste workers, and textile clusters to calibrate our AI systems using real-world textile data and to understand operational challenges as they exist on the ground. These partnerships help us test and refine our solutions across diverse materials and production conditions, ensuring that our technologies are not just advanced, but applicable, accessible, and reliable.

Every tool we design from FibreSENSE to our traceability platforms is built through continuous dialogue and iteration with the people who use it daily. By listening, adapting, and co-developing, we ensure that innovation serves its true purpose: to empower people, improve processes, and create impact where it matters most.

Q. India is becoming a hub for deep-tech innovation. How do partnerships with institutions like IISc and C-CAMP help you turn advanced research into real-world impact?

A. Partnerships with leading research institutions such as the Indian Institute of Science (IISc), the Centre for Cellular and Molecular Platforms (C-CAMP), and the Central Silk Technological Research Institute (CSTRI) are core to how we innovate at KOSHA.ai. These collaborations bridge the gap between academic research and industrial application, allowing us to translate scientific discovery into solutions that work in real-world conditions.

Our AI and molecular fingerprinting systems were co-developed and validated through these partnerships, ensuring scientific accuracy and reliability. Working with such institutions also gives us access to India’s best talent, labs, and interdisciplinary expertise, from material science to data modeling, which accelerates our ability to prototype, test, and scale innovation responsibly.

Q. As the world moves toward more transparency, Digital Product Passports are gaining attention. How do you see them changing the way people buy, use, and trust textile products?

A. Today’s consumers want to know where their products were made, who made them, and under what conditions. This growing expectation for authenticity and accountability has directly influenced how the industry designs, manufactures, and communicates.

The European Union’s Digital Product Passport (DPP) initiative is a clear example of this shift. Soon, every product sold in or entering the EU will require a digital record of its journey, from raw materials to finished goods. This is a consumer-led movement that is driving brands, manufacturers, and innovators to build systems of traceability and accountability across the value chain.

In many ways, transparency has become the new standard of trust and it is inspiring a wave of technological innovation focused on visibility, verification, and circularity.

Q. What does your vision of a “circular textile future” look like — one where fashion, technology, and human well-being come together?

A. Our vision of a circular textile future begins with design, where every product is created with its next life in mind. Materials are chosen for longevity, recyclability, and minimal environmental impact, ensuring that fashion regenerates rather than depletes.

Technology is the enabler of this vision. Through AI, IoT, and molecular fingerprinting, we can build systems that make circularity measurable, traceable, and transparent, from fibre to finished product, and back again. Transparency becomes the bridge that connects design intent with real-world impact. Yet true circularity is not only about materials; it’s about people. From waste workersgaining dignity through safer, tech-enabled work to consumers making informed, responsible choices, human well-being sits at the centre of the loop we’re trying to close.

.jpg)