Yara International is a Norwegian chemical company and one of the global players in crop nutrition. The company has been operating in India for more than two decades. Today, Yara India has a pan-India presence and is working closely with Indian farmers to fulfill the company’s mission to responsibly feed the world and protect the planet.

Yara International is a Norwegian chemical company and one of the global players in crop nutrition. The company has been operating in India for more than two decades. Today, Yara India has a pan-India presence and is working closely with Indian farmers to fulfill the company’s mission to responsibly feed the world and protect the planet.

Yara had acquired Tata Chemicals’ urea business relating to the company’s Babrala plant in Uttar Pradesh in January, 2018. It was India’s first foreign direct investment in the highly regulated urea sector. Recently, the company accomplished a groundbreaking overhaul of this plant, setting a new benchmark for sustainability within the urea manufacturing industry in India. In just 35 days, Yara India's Babrala unit achieved an extraordinary reduction in Specific Energy Consumption of Urea, impressively lowering it to below 5Gcal/MT. The feat has established the plant as one of the most sustainable urea manufacturing facilities in India.

Amidst this journey of transformation, Yara India's commitment to nurturing the local community shines brightly. We showcase heartwarming examples of their community development initiatives in healthcare, education, agriculture, women empowerment, and infrastructure enhancement - endeavors that have positively impacted countless lives in the region.

In this exclusive interview, Mr. Maya Shanker Prasad, Plant Manager, Yara Babrala - Yara Fertilisers India Pvt. Ltd. takes us through their remarkable journey towards sustainability and community development.

Read the full interview for extensive insights to the phenomenal work being done by the company:

Q. Yara India recently completed a significant overhaul of its manufacturing unit in Babrala, Uttar Pradesh- what led the organization to decide on this initiative and how does it align with the broader sustainability goals of Yara India?

A. Yara Babrala takes plant shutdown every two years to carry out the major replacements, equipment overhaul / cleaning and maintaining regulatory compliances for a safe, reliable, and efficient operation; last time, annual turnaround (ATR) of plant was executed in the year 2021. Babrala unit was considered to be the most energy efficient fertilizer plant till year 2018-19 and we enjoyed this position for almost 25 years; later, we lost top spot to a PSU of same vintage. Since then, we brainstormed internally and talked to experts & consultants to build the road map of Babrala. In the recent ATR, we replaced Steam turbines (3 nos), CW pumps (3 nos) & catalysts and carried out modification on few piping & equipment which were bottleneck in plant operation, along from major equipment overhauling, execution of reliability enhancement projects & health checkup of equipment/piping. This led to saving in GHG emissions to a good nos. and improved the plant efficiency.

Q. This overhaul was completed in a record time of 35 days. Could you take us through the process- what were the specific measures that led to achieving the set targets within such a short duration of time?

A. This year, the plant outage started from 3rd March’23 for around 35 days (production to production). This was the biggest and most complex turnaround in the plant history of 29 years of operation, in terms of multiple critical jobs taken at a time, external people mobilized, and invested capital.

Plant turnaround planning requires strategy and careful execution that sees project success to fruition. In planning stage, apart from job detailing, the team had focused on exploring safe devices & tools availability, coordinating early with suppliers, anticipating the unexpected and preparing the quality checks. For Turnaround-2023, the planning initiated from July-21, where the team went through all the detail of jobs and there were more than 100 reviews with the steering committee, before executing it at site.

Q. Was there any external agency/consultancy that helped Yara India in designing or implementing these measures? If so, what was their role in the process?

A. Since year 2021, there were many activities conducted by team with a common objective of achieving the lowest energy goal post ATR-2023. Yara Babrala engaged the Ammonia Technology provider for Ammonia plant study, brainstormed internally on the challenges which plant operation team was facing, visited and/or invited other Fertiliser plants for mutually sharing the knowledge on improving plant efficiency and attended the seminars conducted by Fertiliser Association. Almost 5000 tasks of different nature and complexity were planned in this turnaround. To complete such a high volume of work, around 3000 external persons were mobilized at site through various contractors, which also includes the safety & inspection personnel.

Q. Could you explain how Yara India adheres to the principles of the 7Rs of sustainability within the Babrala site? How have these principles improved energy efficiency and water consumption, or effluent generation?

A. Yara adheres to principle of 7Rs during its business planning, developing the operational strategy. It supports in decision making in optimum use of resources, adherence with air and water norms, and other regulatory compliances.

For better understanding, few example of 7R are as follows:

A. Reduce: This principle focuses on reduction resources through identification and elimination of waste/ misuse.

- Reduction in water abstraction

- Reduction in trade effluent generation

- Reduction in chemicals in DM plant for units’ regeneration

- Reduction in Steam consumption through continual/ break through improvements. This also can be credited for reduction in CO2 generation by reduction of appropriate Natural gas to be used for steam generation.

- Reduction in Neem oil consumption through adopting the latest technology.

- Reduction of generation of floor washing effluent

B. Reuse: This principle focuses on reusing resources for other purpose.

- Use of treated sewage water as Cooling Tower makeup

- Use of Trade effluent as cooling water make up (Planned in 2023-24)

C. Recycle: This principle focuses on recycling the resources after due treatment for same purpose.

- Recycling of Ammonia and Urea Process Condensate

- Recycling of Turbine condensate

- Recycle of Steam condensate

- Recycle of spilled urea through dissolver

- Recycling of all condensate results in almost 80% of freshwater reduction for steam generation.

D. Revise: This principle inspires us to set new target and challenge to our own achieved milestones. Some examples are as below:

- Increase in Urea production (MT per day): 2250 >> 2620 >> 3500 >> 3600 >>3700 (Next Target)

- Increase in Ammonia Production (MT per day) 1350 >> 1520 >> 2000 >> 2100 >> 2200 (Next Target)

- Specific Urea Energy Gcal/ MT 5.2 >> 5.164 >> 5.0 >> 4.95

- Specific Water Consumption Cubic M/ MT of Urea: 4.9 >> 4.7 >> 4.6 >> 4.4 (Next Target)

E. Recharge: This principle inspires us to replenish the natural resources through suitable technology. Some examples are as below.

- Recharge the ground water through making recharge pit in natural flow stream and making pond to collect rainwater. There are four ponds.

- Recharge the ground water through rejuvenating the Ponds and Streams

F. Rethink: This principle inspires us keep innovating and providing a platform to capture the ideas. Some examples are as below:

- AIM (All Idea Matters) platform to capture the ideas of employees (It covers all improvements) like Syn, CO2 and BFW turbine replacement, Header size increase for KS steam.

- Use of Rain runoff water for cooling water make up- 1st Phase-Developed infrastructure for plant catchment area in 2022. 2nd Phase-Infrastructure development to capture the Township catchment area is planned in 2024.

- Use of Rooftop rainwater as cooling water make up- 1st Phase-Infrastructure developed to cover three buildings in plant in 2022. 2nd Phase-Infrastructure development to capture rest of the building in plant is planned in 2023.

- Installation and Use of Solar Power to reduce the fossil fuel consumption. This supports in CO2 reduction objective.

G. Reward and Recognition: This principle focuses on involvement and motivation of employees through rewarding them for their contribution and collaboration. Some examples include Mini Star Awards, STAR Awards and awards for different quizzes (Occupational Safety, Process Safety and Environment)

The Reduce, Reuse, Recycle, and rethink principles supporting to reduce water consumption or effluent generation as explained earlier, while the Reduce and Rethink principles help to improve the energy efficiency.

Q. How does Yara India foster sustainable agricultural practices of water conservation and ensure future food production? Please provide an overview of the extensive soil and water conservation initiatives undertaken by you in Babrala.

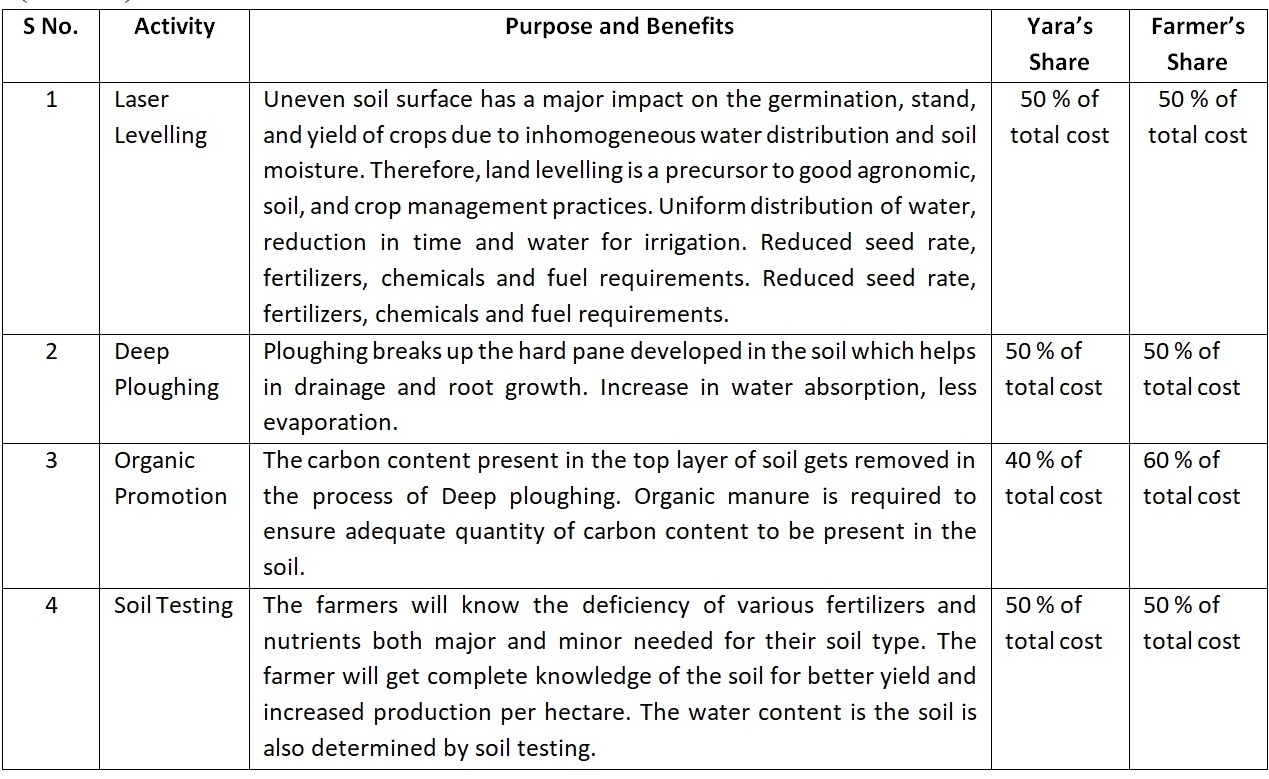

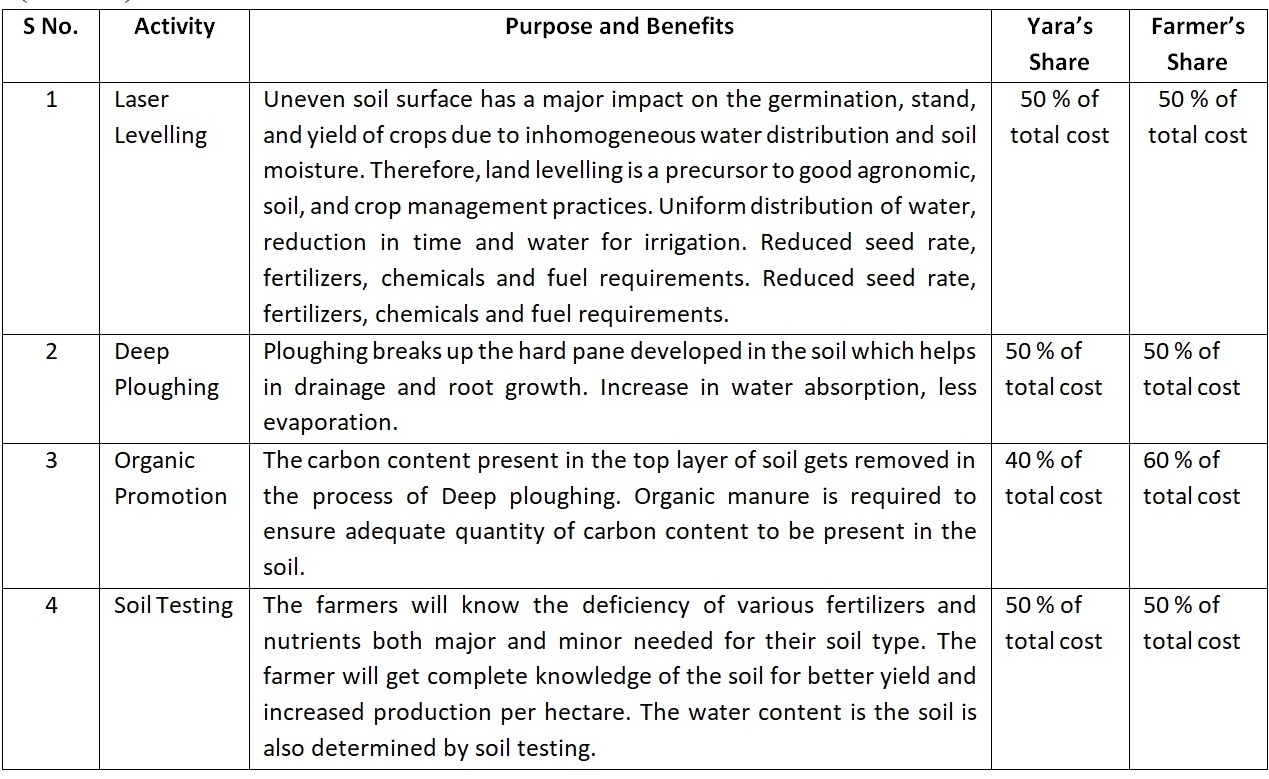

A. a. Soil and water conservation project – covered 150 acres of land in CY 2021 and 200 acres of land in CY 2022. The target for 2023 is 300 acres of land. (Brief introduction of components in Package of Practices and our interventions in the table):

b. Irrigation through underground pipeline introduced in 2022:

- Constructed channel for 33 tube wells

- 3020.60 bigha covered

- 567 farmers benefitted

c. Recycling and reuse of sewage water

- Commissioned MBR based sewage treatment plant

- 54000 M3 treated water recycled and used as Urea cooling tower makeup (600 KLD) for high end application

d. Storm water recovery and reuse

- Developed infrastructure for use of storm water

- 78000 M3 rainwater used as Urea cooling tower makeup

e. Rooftop Rainwater Recovery and Reuse

- Developed infrastructure to use roof top

- 650 M3 rooftop water reused as Ammonia Cooling Tower makeup

f. Water conservation beyond fence

- 4 ponds rejuvenated under Amrit Sarovar Campaign (Area 14430 M2) to collect rainwater

- Water saving in agriculture through deep ploughing and laser levelling (mentioned above). About 25% water saving/crop (Area: 153 acre)

Q. The Babrala plant is described as one of the largest and most sustainable agricultural units in the country. What other factors contribute to its sustainability, aside from the energy efficiency and water conservation initiatives mentioned?

A. Yara Fertilisers India Private Limited is focused on adherence to environmental compliances, which is in line with the company’s mission to protect the planet. Babrala site strives to be the best among industry peers, committed towards the highest standards of environmental responsibility and the use of the best available technologies for sustainable operation. The site is committed to complying with all applicable laws, rules, and regulations and ensures timely submission of compliance reports for all applicable licenses, authorizations, and No objection Certificates. The compliances are continuously monitored, and risk is assessed to fully adhere to changing and stricter environmental laws and regulations. The Babrala site focuses on sustainability by addressing four pillars - Health, Environment, Safety, and Quality.

Yara has focused approach on plant reliability that results into sustenance of energy and energy improvement. These actions result into reduction of carbon footprint. Major Energy Saving / Reliability Projects implemented recently are as follows:

- The Syn gas & 21 CO2 Turbine has been upgraded with the latest design & high-performance turbines leading to steam saving & long terms reliable operation in the plant.

- BFW turbine (TP-601A) replacement with modern designs, higher reliability & energy efficiency turbine.

- The High pressure steam header of one of the Heat Recovery Unit has been modified to reduce the high steam drum pressure in the Boiler, which led to stoppage of Auxiliary Boiler.

- One of the modules of steam superheater was replaced, while chemical cleaning was carried out in other two. It resulted in equipment reliability and higher temperature at Superheater outlet.

- Ammonia Synthesis converter S-200 basket replaced with S-300 with enhanced ammonia conversion.

- Part of Urea Sieve tray replacement with high efficiency Super-Cup tray in Urea-21 stream.

- Installation of NIIK Vortex Mixer in Urea-11 Urea Reactor.

With implementation of all energy saving and plant reliability projects, Yara Babrala site is able to reduce Specific Energy Reduction from 5.2 Gcal/MT Urea to approx 4.95 Gcal/MT Urea. This energy reduction is equivalent to saving of emission by 70,000 MT CO2-e.

Q. What role does the Babrala plant play in driving economic growth and creating employment opportunities in the area? Can you provide examples of collaborations with local stakeholders and suppliers that have positively impacted the community?

A. Yes, we have collaborated with local suppliers (approx 50) who provide inbound/ outbound transportation services, housekeeping services, supplies of consumables items. These suppliers are associated with Yara since more than 15 years now. These suppliers stimulate local economic growth by providing employment opportunities to local people. The plant provides employment to close to 330 permanent and 700 contract staff from in and around Babrala and Sambhal district.

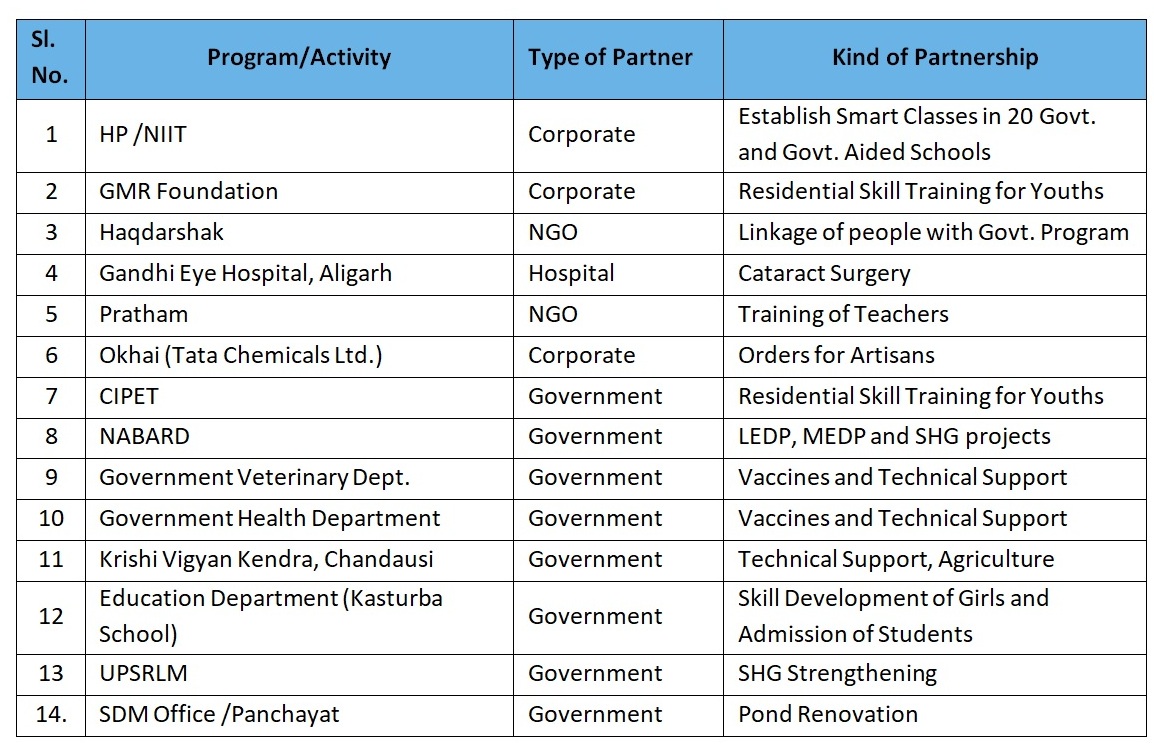

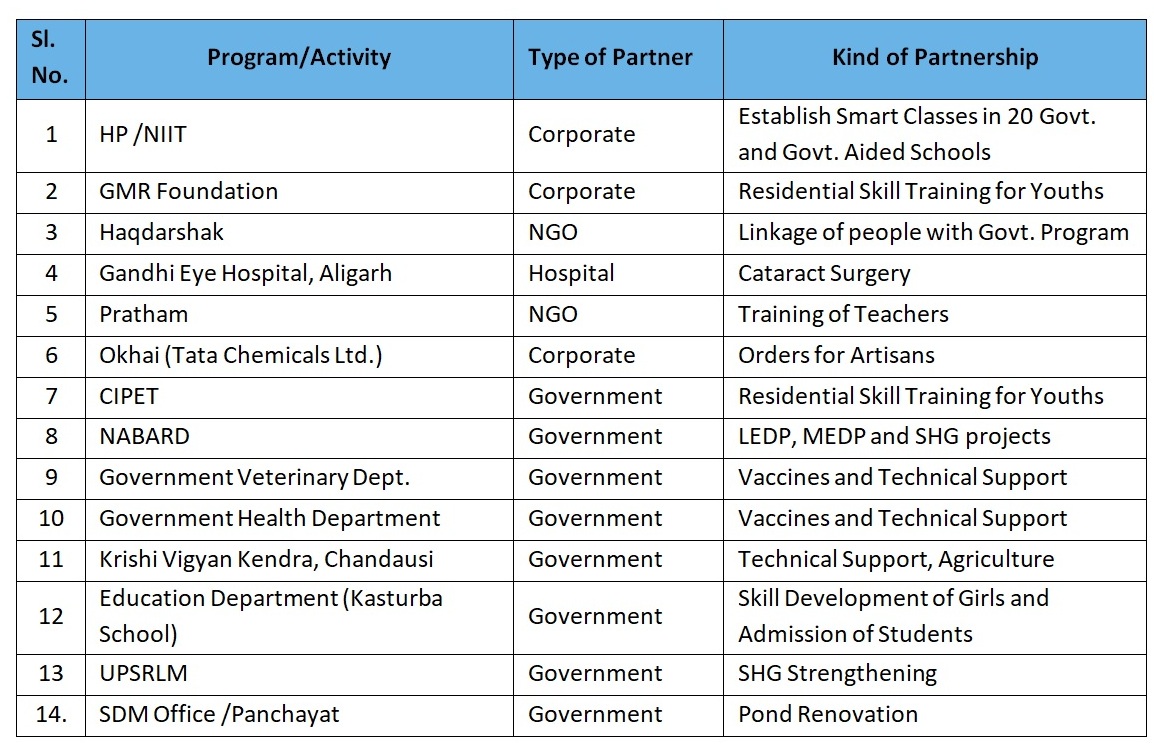

Q. Which NGOs/local bodies/community organisations have you partnered with for your major projects in the area?

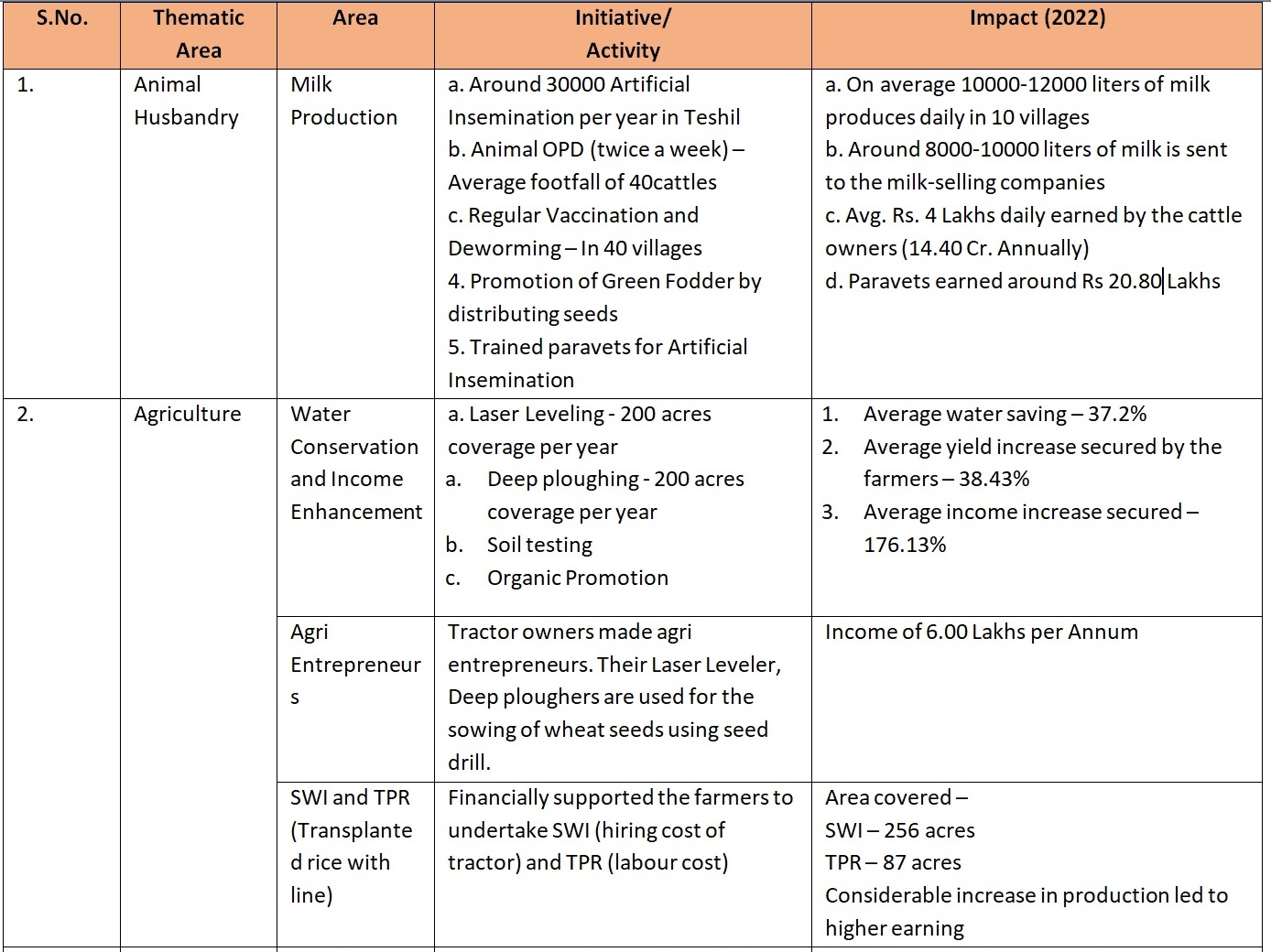

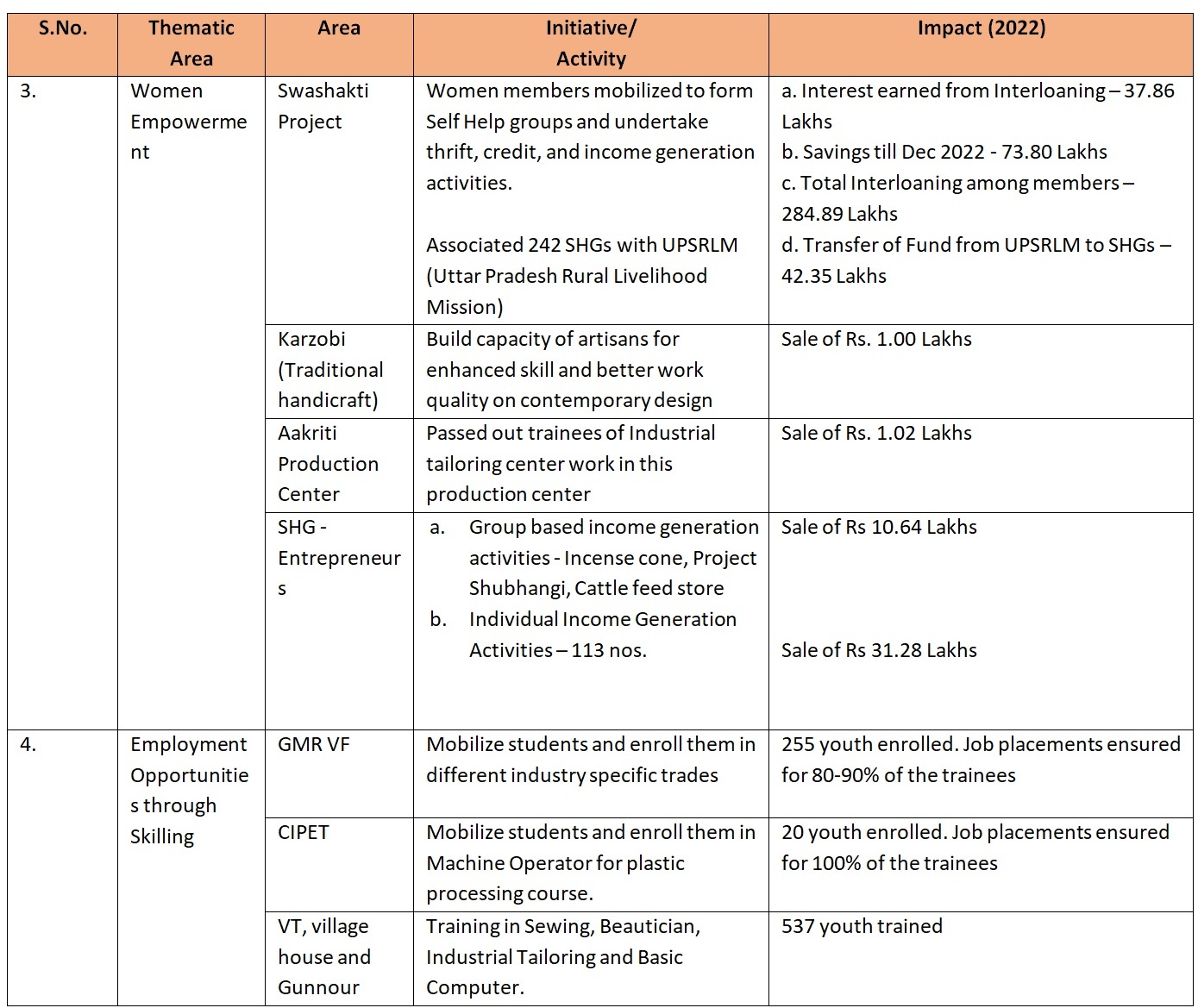

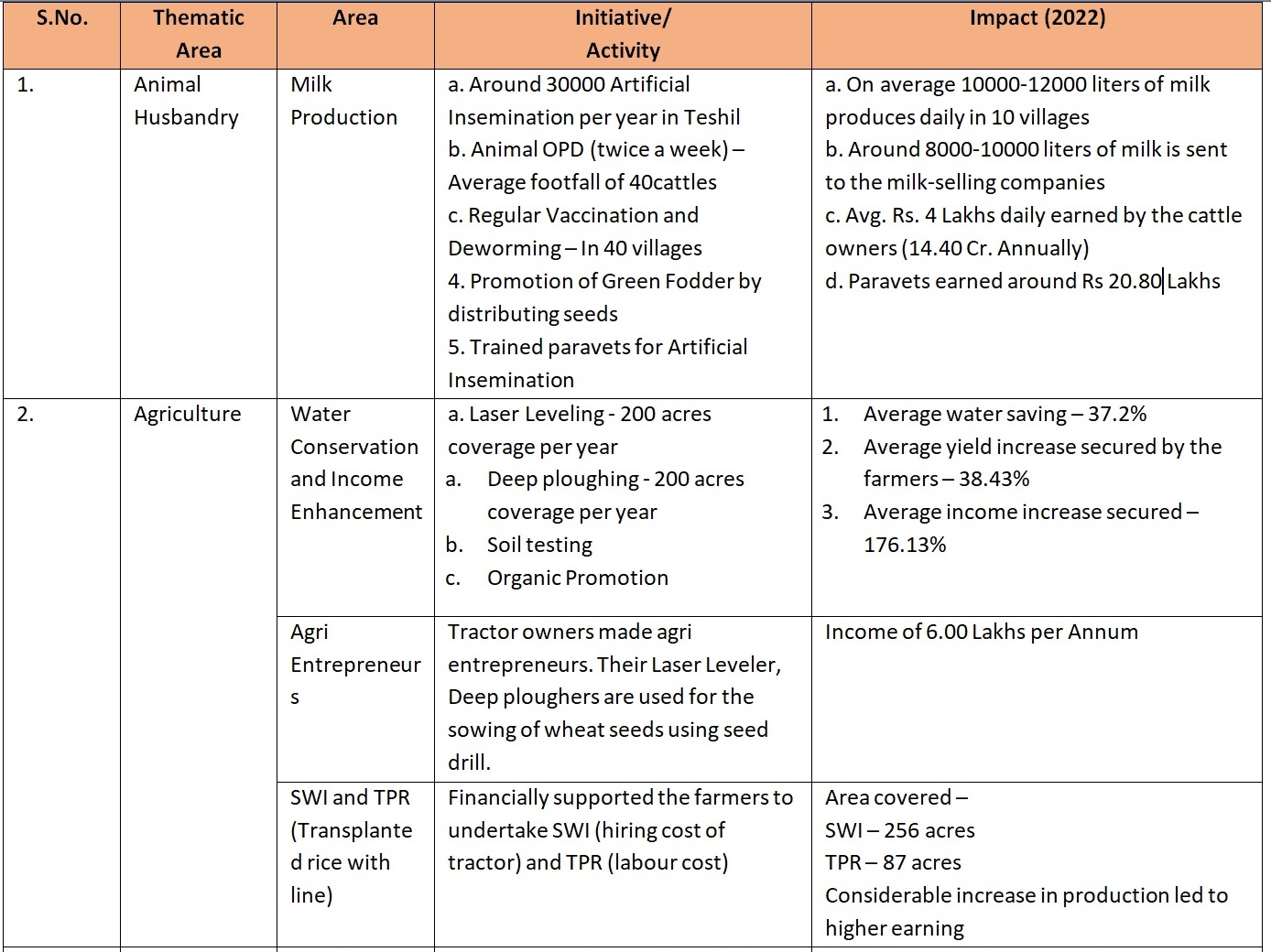

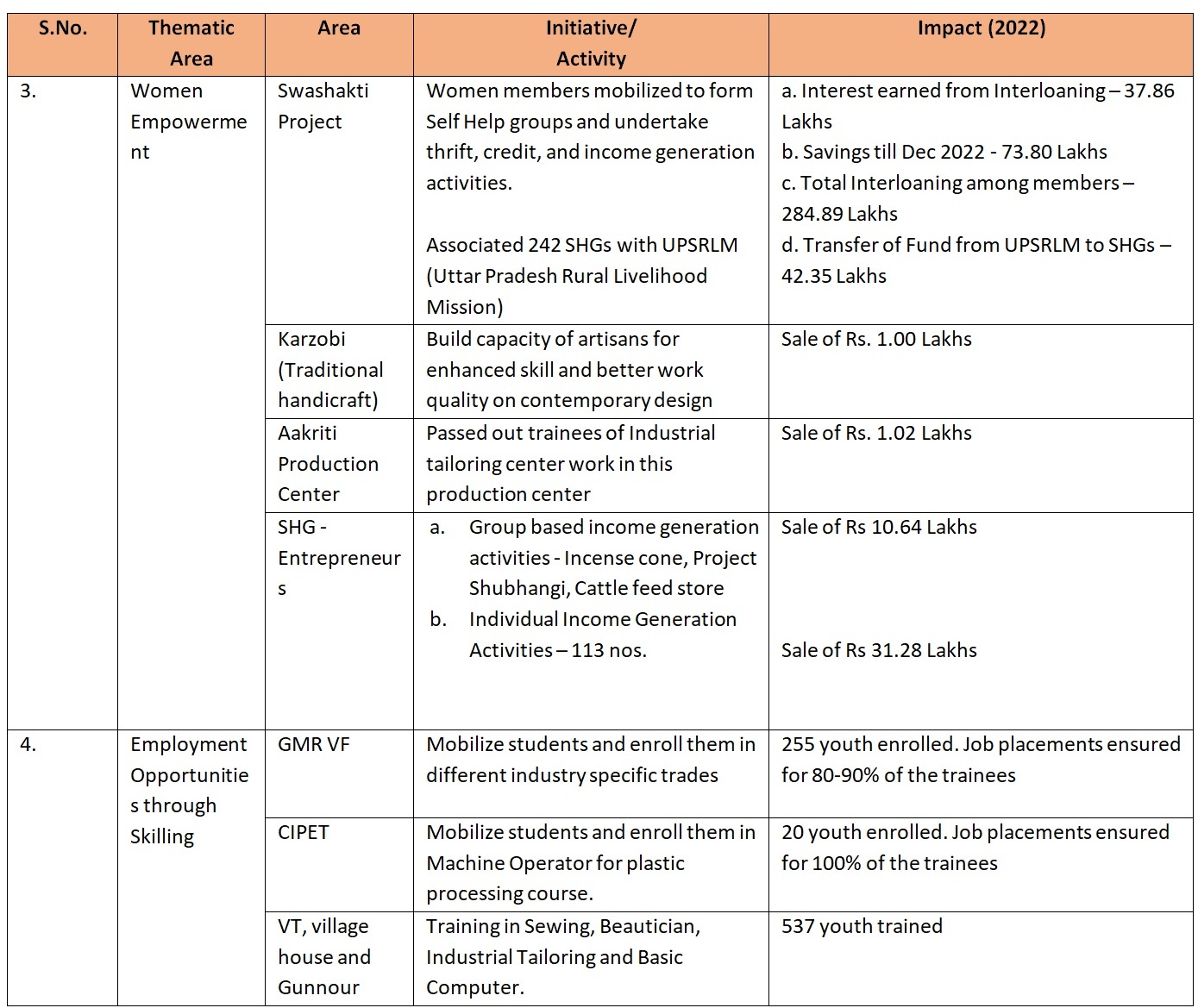

Q. Yara India mentions undertaking various community development initiatives across sectors like healthcare, education, agriculture, animal husbandry, women empowerment, skill development, and infrastructure enhancement. Are there any specific examples or success stories that you would like to share with us?

A. Aligned with Yara India's core values, the Babrala unit has spearheaded community development initiatives across crucial sectors such as healthcare/sanitation, education, agricultural development, animal husbandry, women empowerment/skill development, and infrastructure enhancement. By integrating sustainable practices throughout its operations, the unit has emerged as a catalyst for positive change within the region.

In line with its mission to create a positive societal impact, Yara India has forged meaningful partnerships with numerous NGOs and government bodies. The company is establishing smart classes in 20 government and government-aided schools, fostering educational advancement in underprivileged communities. Moreover, Yara India has organized residential skill training programs, empowering 390 youth with essential vocational skills in the last two years. The company has also made notable contributions to healthcare, facilitating 270 cataract surgeries, 136 prosthetics for amputees and implementing projects of various organizations.

The latest infrastructure development at the Babrala unit includes the construction of channels for 33 tube wells through underground pipeline system, ensuring safe drinking water for the community through RO plants, improvement of 84 cattle sheds covering more than 350 cattle and providing bench and desk for 300 students at Government Schools. With a focus on technological advancement, community development, and environmental sustainability, Yara India continues to set new standards for excellence in the industry.

Yara International is a Norwegian chemical company and one of the global players in crop nutrition. The company has been operating in India for more than two decades. Today, Yara India has a pan-India presence and is working closely with Indian farmers to fulfill the company’s mission to responsibly feed the world and protect the planet.

Yara International is a Norwegian chemical company and one of the global players in crop nutrition. The company has been operating in India for more than two decades. Today, Yara India has a pan-India presence and is working closely with Indian farmers to fulfill the company’s mission to responsibly feed the world and protect the planet.

.jpg)