New Delhi, October 14, 2025: India has launched a five-year initiative, supported by the Global Environment Facility (GEF) and implemented by the United Nations Development Programme (UNDP) in partnership with the Ministry of Electronics and Information Technology (MeitY), to promote a circular economy in the electronics sector. The project aims to ensure the environmentally sound management of e-waste, reduce hazardous material use, and strengthen sustainable recycling systems.

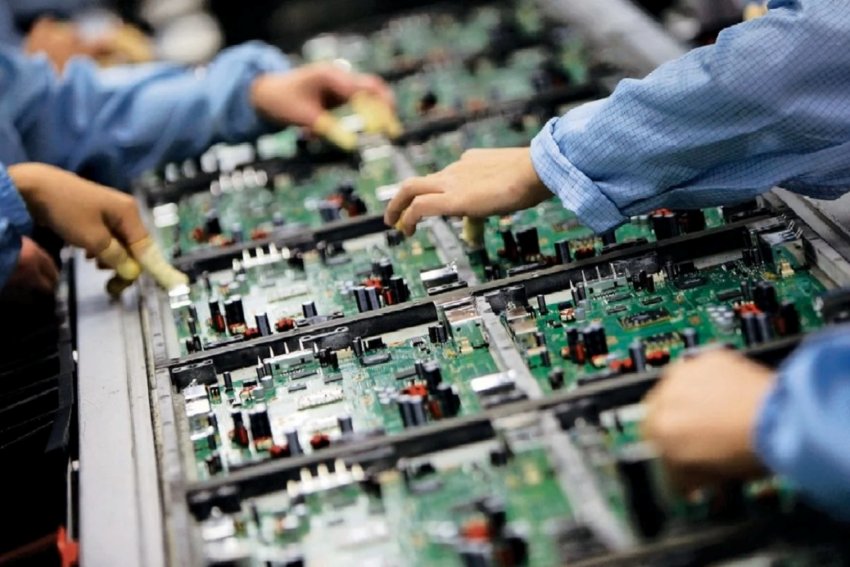

India is the world’s third-largest generator of e-waste, with more than 80% of it processed in the informal sector using unsafe methods that pose serious environmental and health risks. The new initiative will work to formalize the recycling ecosystem, promote eco-design, and improve the recovery of valuable materials while supporting national and international biodiversity and climate goals.

GEF has approved US$15 million in funding for the initiative, which will mobilize an additional US$105 million in co-financing from the Government of India and industry stakeholders. The combined US$120 million investment will strengthen institutional mechanisms, enhance enforcement of e-waste regulations, pilot eco-design innovations, and develop battery management systems for safe recycling and material recovery.

Shri S. Krishnan, Secretary, Ministry of Electronics and Information Technology, said,

“The project comes at an important time when the Indian electronics sector is seeing rapid growth and development. The initiative will help us to drive innovation in eco-design, recycling and circular business models by working closely with industry partners and stakeholders. By promoting circularity, we will improve self-reliance in supply chain of secondary raw materials, create new opportunities, strengthen livelihoods, and safeguard health and the environment.”

Angela Lusigi, UNDP Resident Representative in India, added,

“This project comes at a critical moment when India’s electronics market is expanding rapidly. At the same time, environmental and health risks from unsafe e-waste recycling practices are also rising. We are working with government and industry partners to ensure resources are used efficiently, workers are protected, and the sector grows sustainably. Together, we can turn this challenge into an opportunity for a safer, more sustainable future in alignment with India’s circular economy vision.”

Xiaofang Zhou, Director, UNDP Chemicals and Waste Hub, said,

“This flood of discarded devices contains toxic chemicals, including persistent organic pollutants (POPs), which do not break down easily and cause long-term damage to ecosystems and people’s health. UNDP works with countries, the GEF, and industries to strengthen policies that prevent hazardous chemicals in production, pilot safer recycling models, and recover valuable resources while protecting workers and communities. Addressing e-waste is central to building the circular economy we need for a healthier planet.”

Carlos Manuel Rodríguez, CEO and Chairperson of GEF, stated,

“This project in India is more than a local solution—it can be a model to demonstrate how these toxic chemicals can be designed out of production and safely managed when products are discarded. By supporting this effort, the GEF is helping to chart a path toward cleaner industries and a circular economy that can be replicated in other countries.”

Shri Amitesh Kumar Sinha, Additional Secretary, MeitY, said,

“This project will strengthen Extended Producer Responsibility and Resource Efficiency in the country to meet critical minerals requirements of the electronics sector by promoting collection, environmentally friendly recycling, and formalization of informal workers, especially women, through various circularity pilot projects and training programmes.”

The project will build India’s capacity to implement the E-Waste (Management) Rules 2022 and contribute to the National Policy on Electronics. It is expected to benefit more than 6,400 people directly and reduce environmental risks by preventing the release of 8,000 tonnes of toxic heavy metals, eliminating 25 tonnes of hazardous flame retardants, and cutting 600,000 tonnes of CO₂-equivalent emissions.

.jpg)