Sustainability isn't merely a buzzword. Organizations like PLUSS Advanced Technologies are taking a leading role by actively addressing environmental challenges through advancements in material science. This field explores how a material's composition and structure influence its properties. PLUSS leverages this knowledge to develop cutting-edge thermal solutions, such as Phase Change Materials (PCMs). These PCMs find applications in sustainable agriculture, improved thermal management systems, and wearable cooling technology.

In this exclusive interview, Mr. Samit Jain, Managing Director, PLUSS Advanced Technologies, dives into the company's groundbreaking work in developing advanced thermal solutions for a more sustainable future. PLUSS, a subsidiary of Carborundum Universal and part of the Murugappa Group, embodies the philosophy of "Making Materials Matter." Their dedication to pioneering PCMs fuels their mission to enhance sustainability, efficiency, and well-being across various industries. Ultimately, PLUSS aspires to create a brighter future for all.

Read the full interview below to delve deeper into these areas and explore how PLUSS Advanced Tecnologies' advancements are making a positive impact.

Q&A

Q. Can you elaborate on PLUSS Advanced Technologies' overall mission and vision for the future, and how your innovations in areas like sustainable agriculture, thermal management, and wearable cooling technology align with these goals?

A. It goes without saying that everything around us revolve around materials. A subsidiary of Carborundum Universal, a Murugappa group company, we at PLUSS strive to “Make Materials Matter”. We pioneered speciality materials for improving properties of polymer materials, recycling of polymer materials and enabling storage of energy – both heat and cold. Our overarching mission is to pioneer innovative thermal solutions that enhance sustainability, efficiency, and comfort across various industries and applications. This is done through the materials that we make, called Phase Change materials (PCMs).

At the core of our vision for the future is a commitment to materials and technologies to address pressing global challenges like reducing wastage of energy, increasing energy efficiency, food and vaccine safety and reducing food loss just to name a few. By prioritizing sustainability, efficiency and well-being, we aim to create a brighter and more sustainable future for all.

Q. What are your primary focus areas in research, development, and application of Phase Change Materials (PCMs) and other advanced technologies? How do these contribute to social impact goals like sustainability, farmer welfare, and worker safety?

A. Our research and development efforts center on creating sustainable solutions that minimize environmental impact and promote resource efficiency. We invest in the development of PCM-based materials and systems for energy storage, thermal management, and temperature regulation, enabling industries to reduce carbon emissions, optimize energy usage, and adopt more sustainable practices.

PLUSS is dedicated to improving farmer welfare through innovative agricultural solutions. We develop PCM-based technologies for Fruits and vegetable storage and transportation, helping farmers mitigate post-harvest losses. By enhancing crop quality and marketability, our solutions contribute to the economic empowerment and livelihood improvement of farmers.

Human comfort and safety is a top priority in our research and development initiatives. We focus on developing wearable cooling technology and thermal management solutions to protect workers from heat stress and fatigue in hot and humid environments.

Q. What emerging trends do you see for PCM use in different sectors, and what challenges do you foresee for PLUSS in the coming years? How are you preparing to navigate challenges and capitalize on opportunities to address social and environmental needs?

A. Cooling is going to be the biggest challenge to address in an increasingly warming world. The rural parts which need cooling most, are the ones who cannot afford it. So, even if we have solutions, how do we work out business models that will enable mass adoption of our technologies for prevention of food loss and doubling of farmers incomes at the grassroots level.

There will be increased adoption of PCMs in building cooling and heating, as the construction industry matures. We also see adoption of PCM in clothing in the long run, as the technology matures and becomes more affordable.

Vaccine wastage and inefficacy due to inappropriate temperatures through the supply chain is something that we are addressing on a war footing. Developing easy to use solutions for vaccine transport and enabling their reuse is also being worked on.

A lot of packaging for food or pharma, need to be sustainable. We are working on newer materials for insulations to help address sustainability issues due to indiscriminate disposal.

Q. Since you use indigenous materials and processes, how do you integrate this commitment into the company's long-term goals (5-10 years) for operations and product development?

A. Creating in India for the world, has been our motto since inception. Any design or development that is undertaken, revolves around identifying what is locally available as much as possible. We also work with our suppliers to be able to have our requirements met indigenously. In addition, our customers who currently import, we work with them to help develop the right material locally. India does have a challenge that several basic ingredients are not made in India, however with the increase focus on enabling this by the government, we hope in the coming 5-10 years this issue will be addressed.

Q. PLUSS' Aagun dryer and PronGO cold storage boxes directly address food security challenges. Can you share how these projects have impacted farmers' incomes and reduced food spoilage? Have you quantified these measurable outcomes?

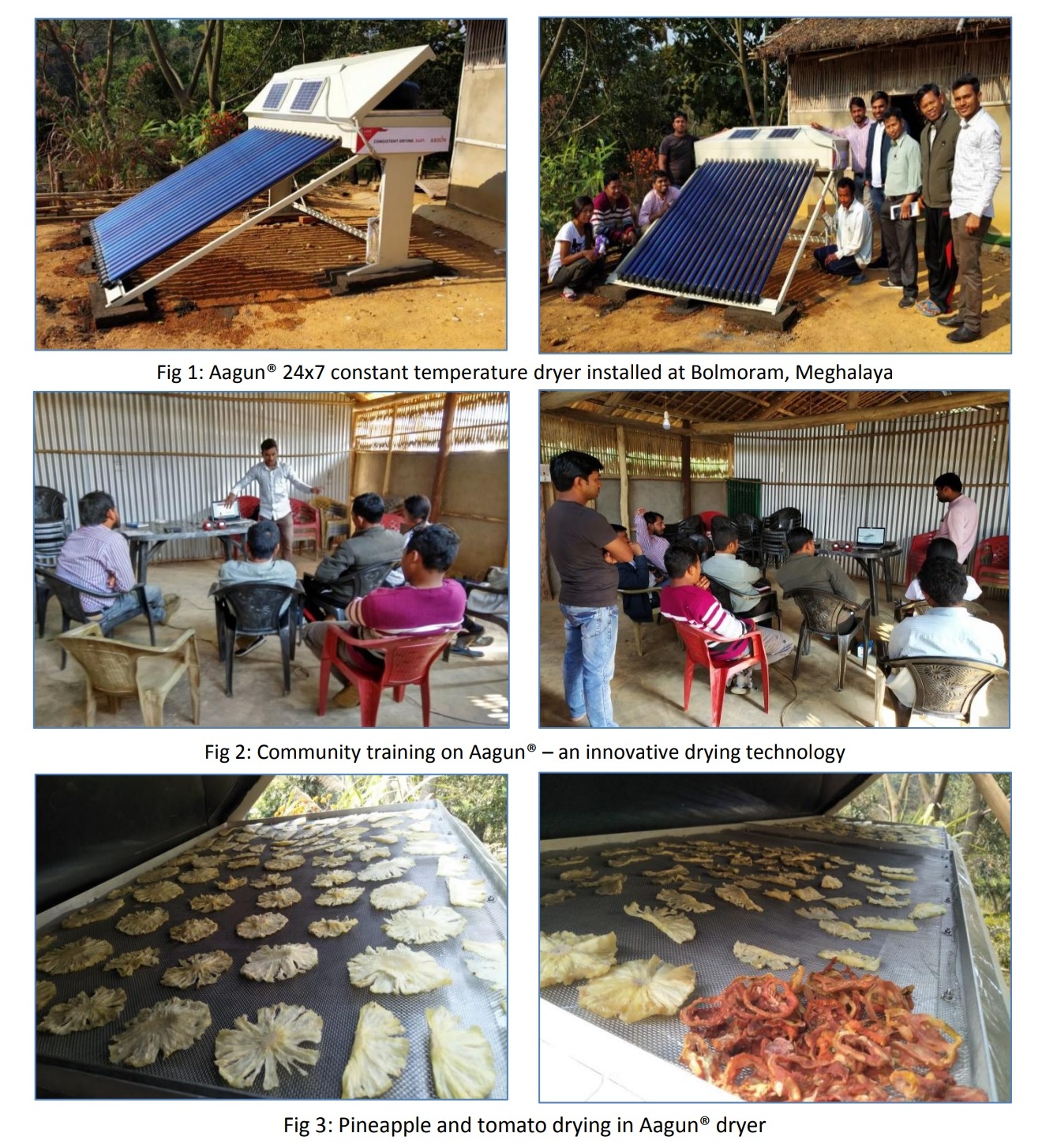

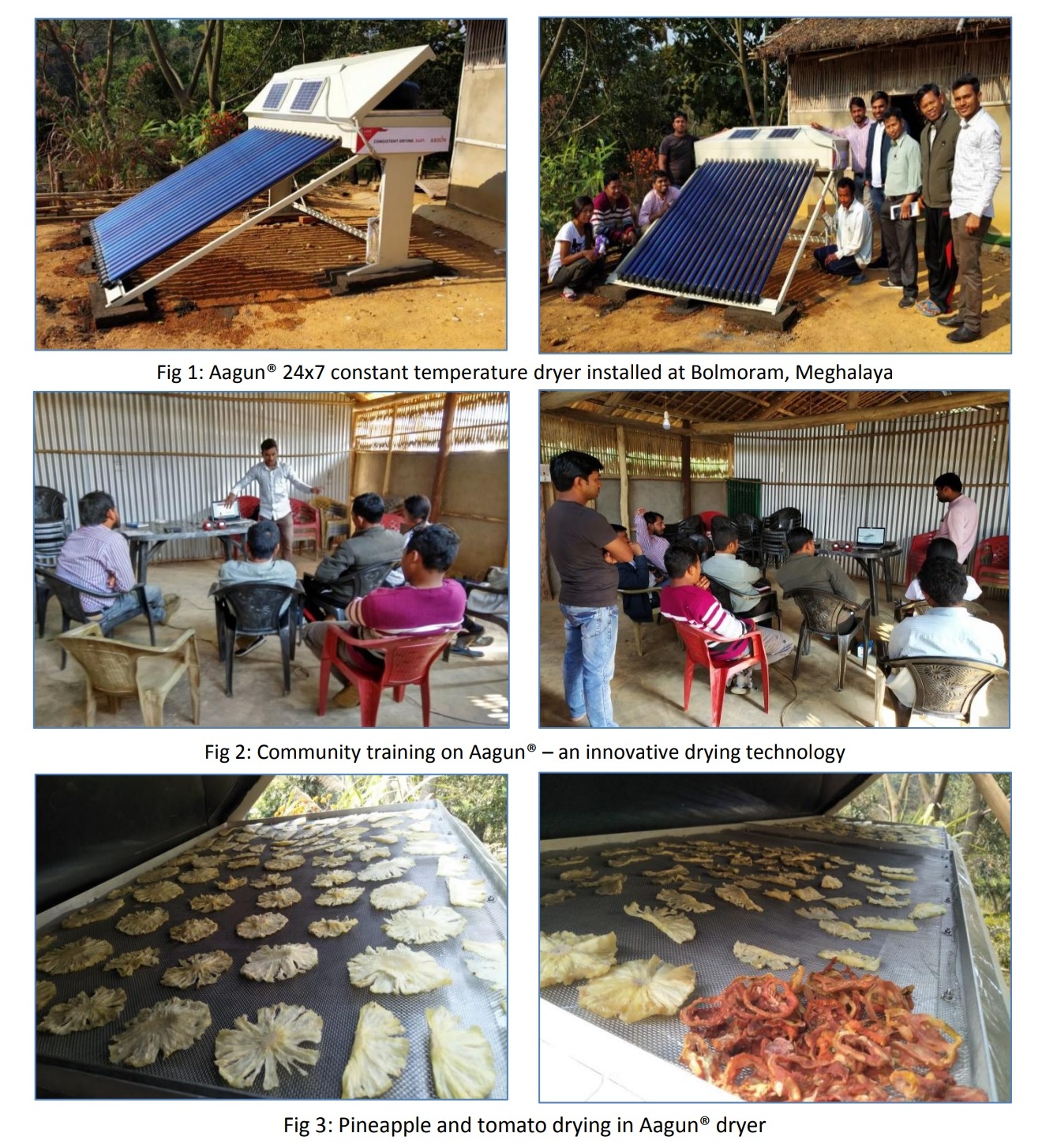

A. So, we have seen and recorded at sites where our products have been used to add value to farmers with the help of the respective state governments, typically reducing food wastage upto 30% due to improved linkages between farm and markets. Also, farmers are able to gain more value for their crops by keeping them fresh for longer. Distress selling by farmers has been avoided. Our cold-rooms at the farmgate have enabled farmers keep produce at the right temperature until they are sold. In the case of Aagun, we have seen farmers being able to value add to their crops by improving their yield of drying and gaining more returns out of these products. Pilots done in the north-east and Tamil Nadu, have shown farmers getting over 5x return on dried products like pineapple in North East and chillies, buttermilk coated/dipped vegetables like bitter gourd and ladies fingers in the South.

Q. How does the company envision these technologies transforming global food security, especially in regions with limited resources?

A. In the case of products like Himacool and Aagun, which are developed by integrating solar panels along with thermal storage, these especially work well in areas which have less access to consistent grid power. Not only do these solar and thermal batteries give you alternate energy efficient solution but also provide farmers with consistent cold storage and drying facilities throughout the year. Both products do not need any grid connectivity and are ideal examples for distributed renewable energy at the farm level.

Q. How does PLUSS foster a culture of innovation? Can you share successful partnerships that have driven the development and deployment of solutions for low-income workers or vulnerable populations?

A. Albert Einsten said, “Imagination is more important than knowledge”. We encourage our teams to think differently, think out of the box, and take risks. A lot of freedom is given to team members, even fresh graduates to create. We encourage them to work in cross functional teams and move people around to enable them acquire diverse knowledge and skill sets.

Collaboration has been the key for developing our products. At the product development level, we for instance, partnered with Christian Medical College, Vellore to develop the MiraCradle – an affordable device – at 1/10th the cost of imported devices. Similarly, we are working with NGOs like Advit Foundation, to propagate our cold-rooms and dryers in village settings to train and expose low-income workers/farmers with newer technologies.

Q. How does the company gather and incorporate customer feedback, particularly from rural communities or low-income sectors, to improve products and ensure social relevance and accessibility? Can you provide an example of how feedback has led to product improvement or innovation with a positive social impact

A. We stay in touch with our customers and work with the governments to define specifications of these products which have been gathered from/at district levels. Product improvement is a constant process and we at PLUSS, keep incorporating feedback from customers while also brainstorming internally on how to add further value to our customers using our thermal storage materials.

For example, when we first launched Aagun, we were told that we could reduce the footprint of the machine and make it more installation friendly by our customers. In a year’s time, we launched Aagun v2. Which was more compact and easier to install and maintain. Similarly, our HimaCool – 24x7 solar cold-room has seen improvements since launch over 5 years back. Farmer requests for temperatures that needed to be different for different produce, these models were also introduced subsequently.

Q. Can you share any notable success stories from your innovations that have specifically addressed social or environmental challenges? How have these achievements made a positive impact on communities or industries?

A. Take the Miracradle for example- our patented and award winning device for neonatal cooling to treat birth asphyxia which has saved the lives of over 20,000 babies in india by deterring the onset of conditions like autism and cererbral palsy. It is only a fraction of the cost of machines that most big hospitals only have, but is also clinically proven for treating birth asphyxia by inducing therapeutic hypothermia for low income regions. Hundreds of hospitals in tier 2 and 3 cities including remote districts in India have benefitted from this solutions. Over 600 hospitals in India use this device. Birth Asphyia is most common in rural settings. PLUSS has made an impact across various industry segments by saving vaccines, reducing food wastage, improving energy efficiency etc; to name a few.

Case study for fruit drying using Aagun™ 24/7 solar dryer

Case study for fruit drying using Aagun™ 24/7 solar dryer

The Aagun™ 24/7 solar dryer, utilizing PCM technology, revolutionizes food drying by replacing inefficient fuel-based methods and enhancing yield quality and quantity. PCM absorbs and stores excess heat during the day, releasing it during non-sun hours, ensuring continuous drying. It can increase output sixfold compared to greenhouse solar dryers with the same footprint. One Aagun™ dryer, occupying 42 sq.ft, can produce up to 800 kgs of dehydrated fruit in six months, whereas a solar greenhouse dryer would need 250 sq.ft for the same yield. The payback period for Aagun™ versus an electric dryer is about 1.6 years. The Aagun™ dryer provides hygienic, consistent temperature drying, resulting in higher quality, nutritionally superior products. Cost-benefit analysis shows that the Aagun™ dryer has significantly lower operating costs compared to electric dryers, making it a more economical long-term solution.

PCM-Based Solar Micro Cold Room: Himacool's Success Story in Nepal

PCM-Based Solar Micro Cold Room: Himacool's Success Story in Nepal

Nepal faces significant postharvest losses of 20-30% for fruits and vegetables due to inadequate storage, improper handling, and poor transportation. To combat this, PLUSS Advanced Technologies introduced a PCM-based solar micro cold room that utilizes solar energy for refrigeration, storing excess cold in PCM plates for use during non-sun hours. This system maintains a constant temperature of 2-8°C without relying on grid electricity or fuel, providing a sustainable and energy-efficient solution.

The innovative cold room allows farmers to store various produce, reducing wastage, improving quality, and increasing market value. Despite initial high investment costs, it offers significant benefits, such as higher bargaining power for farmers and potential rural entrepreneurship opportunities. Additionally, the PCM-based cold room supports sustainable development goals like Zero Hunger, Affordable and Clean Energy, and Climate Action, by minimizing food wastage and increasing farmers' incomes.

Q. What larger social and environmental impact does PLUSS aim to achieve with its innovations? How do you measure success in these areas to ensure a positive and lasting impact?

A. We are and have been a people centric and climate positive company. Today, measuring success in terms of Carbon dioxide reduction is a standard way and we look at adopting that for our solutions. This helps our customers market themselves as carbon responsible. Success need not always be measured with sales and corresponding revenue. Measuring the impact of our actions to help conserve the environment is important.

India has a great responsibility of becoming a developed country with 1/3 or less of the resources that the developed world used to become developed. We have a large population and each individual has aspirations. Our products should help achieve that.

We have defined the word Plusstainable – the ability to meet the needs of the present generation, without compromising the needs of the future. That is our aim.

Case study for fruit drying using Aagun™ 24/7 solar dryer

Case study for fruit drying using Aagun™ 24/7 solar dryer PCM-Based Solar Micro Cold Room: Himacool's Success Story in Nepal

PCM-Based Solar Micro Cold Room: Himacool's Success Story in Nepal

.jpg)